Exploring Laser Engraving with [Product Name]: A Comprehensive Guide

Laser engraving has become one of the most versatile and precise methods for creating custom designs, patterns, and text on various materials. Whether you’re working in woodworking, metalworking, or even crafting, a laser engraving company offers tools that can elevate your projects to new heights. In this article, we’ll dive into the world of laser engraving, exploring its applications, benefits, and how you can get started with a reliable laser engraving company. So, let’s begin!

What is Laser Engraving?

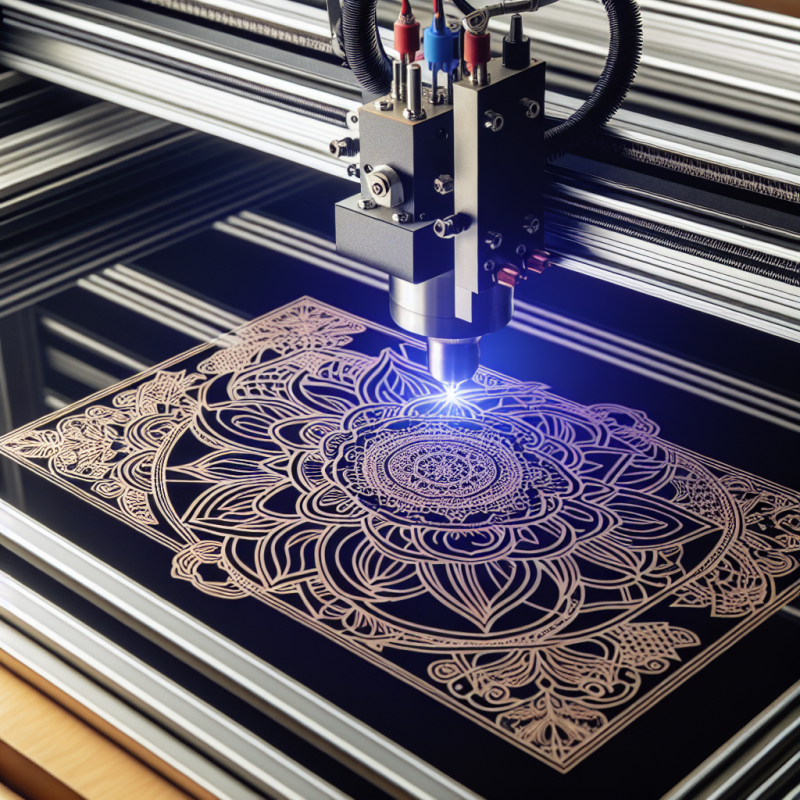

Laser engraving is a process that uses a focused laser beam to remove material from the surface of an object, leaving behind a permanent and precise design. Unlike traditional engraving methods, which rely on mechanical cutting or burning, laser engraving offers unparalleled accuracy and versatility. It can be used on materials such as wood, metal, plastic, glass, and leather, making it a popular choice for both hobbyists and professionals.

The process involves directing the laser beam at high speeds across the material’s surface. The heat from the laser vaporizes or burns away the material, creating intricate designs or text. This method is not only faster but also produces cleaner results compared to manual engraving techniques.

Why Choose Laser Engraving?

There are several reasons why laser engraving has become a go-to solution for many crafters and manufacturers:

- Precision and Detail: Laser engraving allows for intricate designs and text that would be difficult to achieve with traditional methods.

- Versatility: It works on a wide range of materials, making it suitable for various projects.

- Speed: The laser beam moves quickly across the material, reducing production time compared to manual engraving.

- Durability: The engraved designs are permanent and resistant to wear and tear.

If you’re considering investing in a laser engraving machine, partnering with a reputable laser engraving company can ensure you receive high-quality equipment and support.

How Does Laser Engraving Work?

To understand how laser engraving works, let’s break it down into simple steps:

- Design Creation: First, you create a digital design using software like Adobe Illustrator or CorelDRAW. This design will guide the laser beam during the engraving process.

- Laser Setup: The design is then uploaded to the laser engraving machine. Depending on the material and desired depth of engraving, you’ll adjust settings such as power, speed, and focus.

- Engraving Process: The laser beam follows the digital design, removing material layer by layer to create the final product.

- Finishing Touches: After engraving, you may sand or polish the surface to enhance the design’s appearance.

This process is not only efficient but also allows for customizations that suit your specific needs. Whether you’re creating personalized jewelry, decorative items, or promotional products, laser engraving offers endless possibilities.

Applications of Laser Engraving

Laser engraving is a versatile technique with applications across multiple industries:

- Jewelry Making: Engrave intricate patterns or names on rings, bracelets, and necklaces.

- Furniture: Add decorative designs or initials to wooden furniture pieces.

- Marketing and Branding: Create custom logos or promotional items like pens, keychains, and phone cases.

- Metalworking: Engrave metal components for industrial applications or artistic projects.

With the right equipment and expertise from a trusted laser engraving company, you can unlock these possibilities and more.

Choosing the Right Laser Engraving Company

When selecting a laser engraving company, it’s essential to consider factors such as equipment quality, customer support, and pricing. Here are some tips to help you make an informed decision:

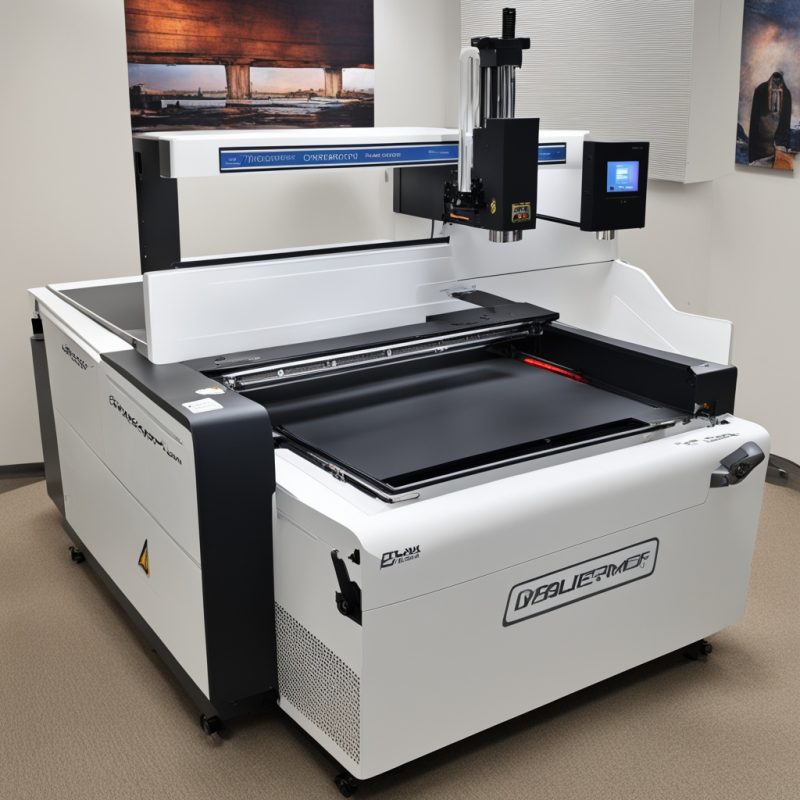

- Research Equipment: Look for companies that offer machines with high precision and versatility. A reliable machine should be capable of handling multiple materials and producing detailed engravings.

- Customer Support: Choose a company that provides excellent customer service, including technical support and training resources.

- Price: While cost is an important factor, avoid compromising on quality. A higher-priced machine may offer better durability and performance in the long run.

A trusted laser engraving company will guide you through the selection process, ensuring you find the perfect machine for your needs.

Maintenance and Care for Laser Engraving Machines

To ensure your laser engraving machine operates efficiently for years to come, proper maintenance is crucial. Here are some tips:

- Clean Regularly: Dust and debris can accumulate on the machine’s surfaces and lenses. Clean these areas regularly to maintain optimal performance.

- Check Alignment: Misaligned laser beams can lead to poor engraving results. Periodically check and adjust the alignment as needed.

- Replace Consumables: Laser engraving machines require consumable parts like lenses, mirrors, and nozzles. Replace these components when they show signs of wear or damage.

By following these maintenance tips, you can extend the lifespan of your laser engraving machine and ensure consistent results in your projects.

The Future of Laser Engraving

As technology continues to evolve, so does the field of laser engraving. Innovations such as 3D laser engraving and multicolor engraving are opening new doors for creativity. These advancements allow artists and manufacturers to create more complex and visually appealing designs than ever before.

Moreover, the rise of eco-friendly practices is influencing the laser engraving industry. Many companies are now focusing on sustainable materials and energy-efficient machines, making laser engraving a greener option for custom projects.

Frequently Asked Questions

1. What materials can be used with laser engraving?

Laser engraving works on a variety of materials, including wood, metal, plastic, glass, and leather. The choice of material depends on the project’s requirements and the machine’s capabilities.

2. Is laser engraving safe?

Yes, laser engraving is generally safe when proper precautions are taken. This includes wearing protective eyewear, ensuring adequate ventilation, and following manufacturer guidelines for machine operation.

3. Can I learn to use a laser engraving machine on my own?

While there is a learning curve, many laser engraving machines come with user-friendly interfaces and software tutorials. Additionally, reputable companies often provide training resources or workshops to help you get started.

Conclusion

Laser engraving is a powerful tool that combines precision, versatility, and creativity. Whether you’re a hobbyist looking to enhance your craft or a business owner seeking efficient production methods, investing in a reliable can open up endless possibilities. With the right equipment and care, you can bring your creative visions to life and achieve professional-quality results in no time.