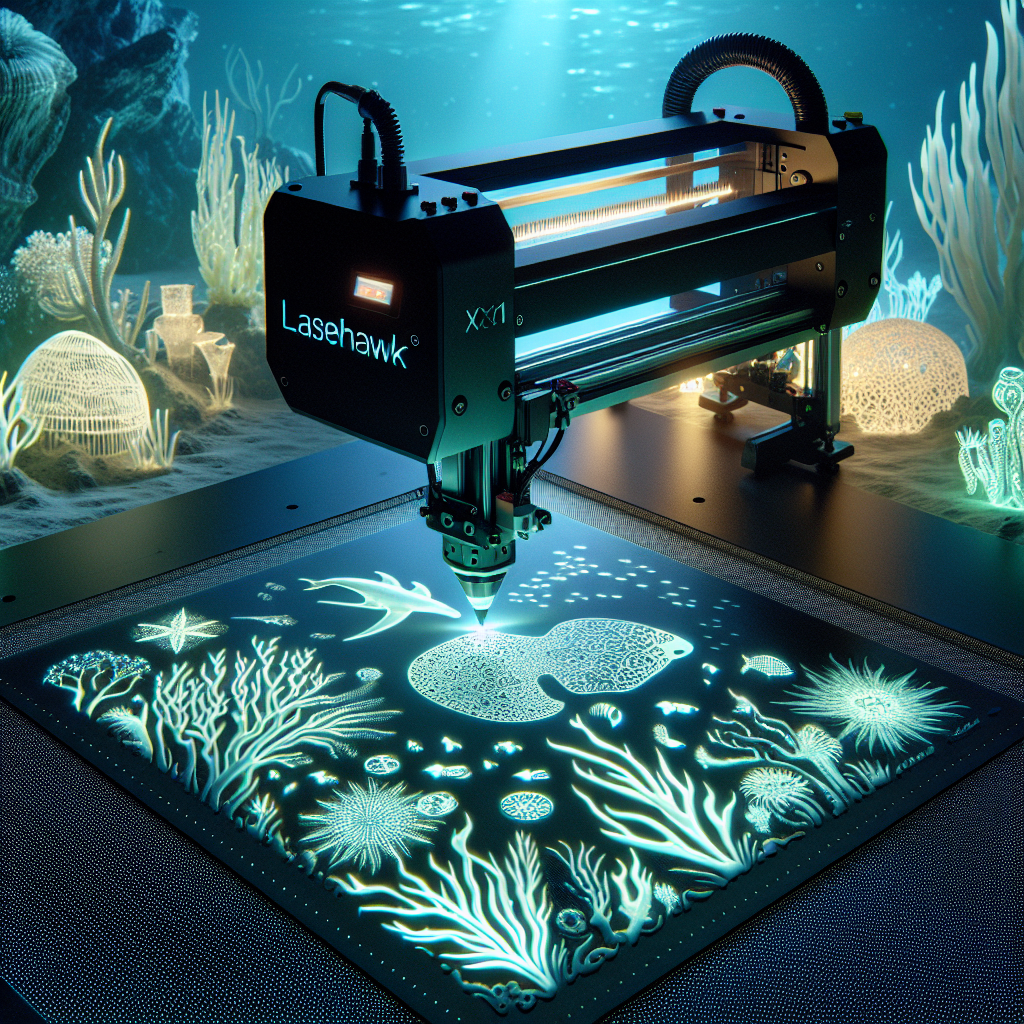

Laser Cutter Acrylic: A Comprehensive Guide

Laser cutting technology has revolutionized the way we shape and design materials. Among its many applications, *laser cutter acrylic* stands out as a versatile tool for precision crafting. Whether you’re a hobbyist or a professional, this article will guide you through everything you need to know about laser cutter acrylic machines, their benefits, and how they can transform your projects.

What Is a Laser Cutter Acrylic Machine?

A *laser cutter acrylic* machine uses focused light beams to cut or engrave materials like acrylic, wood, metal, and more. Unlike traditional cutting tools, laser cutters offer unparalleled precision and versatility. The machine emits a high-powered laser that vaporizes the material along the desired path, leaving behind clean and precise cuts.

If you’re wondering, “What makes laser cutter acrylic machines so popular?” the answer lies in their ability to handle intricate designs with ease. Whether you’re creating custom signs, decorative items, or functional parts, these machines deliver consistent results every time. Plus, they’re easy to use, making them ideal for both beginners and experienced crafters.

How Does a Laser Cutter Acrylic Machine Work?

The *laser cutter acrylic* machine works by focusing a laser beam onto the material’s surface. The intense heat generated by the laser vaporizes or melts the material, creating precise cuts or engravings. Here’s a step-by-step breakdown of how it operates:

- 1. **Design Creation**: Create your design using specialized software like CorelDRAW or Adobe Illustrator.

- 2. **File Upload**: Transfer the design to the laser cutter acrylic machine via USB or a direct connection.

- 3. **Material Setup**: Place the acrylic sheet or other material onto the machine’s bed and secure it in place.

- 4. **Laser Engraving/Cutting**: The machine reads the design file and uses the laser to cut or engrave the material as programmed.

If you’re curious, “Can I use a laser cutter acrylic machine for other materials?” Yes! While acrylic is a common choice due to its ease of cutting, these machines can also handle wood, metal, glass, and even fabric with the right settings. This versatility makes them an excellent investment for various creative projects.

Benefits of Using a Laser Cutter Acrylic Machine

The advantages of using a *laser cutter acrylic* machine are numerous:

- Precision and Accuracy: The laser beam ensures clean, precise cuts with minimal material waste.

- Versatility: Capable of cutting or engraving multiple materials, making it a multi-functional tool for any workshop.

- User-Friendly: Most models come with intuitive software and controls, making them accessible even to first-time users.

- Time-Saving: Automated processes reduce the time spent on manual cutting or engraving tasks.

If you’re thinking, “Is a laser cutter acrylic machine worth the investment?” Consider the long-term savings and efficiency gains. Once you invest in one, you’ll wonder how you ever managed without it!

Applications of Laser Cutter Acrylic Machines

Laser cutter acrylic machines are incredibly versatile and can be used for a wide range of applications:

- Crafts and Hobbies: Create custom signs, decorative items, and unique gifts.

- Prototyping: Quickly produce prototypes for testing before full-scale production.

- Industrial Use: Cut intricate parts for machinery or automotive components.

- Fine Art: Engrave detailed designs onto various materials for artistic purposes.

If you’re exploring, “What industries benefit most from laser cutter acrylic machines?” The answer includes manufacturing, advertising, furniture making, and even the jewelry industry. Their adaptability makes them a valuable tool across multiple sectors.

Top Features to Look for in a Laser Cutter Acrylic Machine

When shopping for a *laser cutter acrylic* machine, consider these key features:

- Laser Power: Higher wattage lasers offer more versatility and speed but may come at a higher cost.

- Cutting Speed: Faster machines are ideal for high-volume projects.

- Bed Size: Choose a machine with a bed size that accommodates your typical project dimensions.

- Software Compatibility: Ensure the machine supports popular design software for ease of use.

If you’re asking, “What’s the best laser cutter acrylic machine for my needs?” Consider your budget and intended use. Entry-level models are perfect for hobbyists, while professionals may require more robust industrial-grade machines.

Maintenance Tips for Laser Cutter Acrylic Machines

To keep your *laser cutter acrylic* machine running smoothly, follow these maintenance tips:

- Clean Regularly: Dust and debris can interfere with the laser’s performance. Clean the bed and lenses regularly.

- Inspect Components: Check for wear and tear on belts, pulleys, and other moving parts.

- Lubricate Moving Parts: Apply a small amount of lubricant to ensure smooth operation.

- Update Software: Keep the machine’s software up-to-date for optimal performance and new features.

If you’re wondering, “How often should I maintain my laser cutter acrylic machine?” Regular maintenance is key. Aim to clean and inspect your machine at least once a month or more frequently if used intensively.

Frequently Asked Questions About Laser Cutter Acrylic Machines

Here are answers to some common questions about *laser cutter acrylic* machines:

- Q: Can I cut thick materials with a laser cutter acrylic machine?

- A: Yes, but thicker materials require higher wattage lasers for effective cutting. Always check the machine’s specifications.

- Q: Is it safe to use a laser cutter acrylic machine at home?

- A: Absolutely! Modern machines are designed with safety features like emergency stop buttons and enclosed housings to protect users from laser exposure.

- Q: How long does it take to learn how to use a laser cutter acrylic machine?

- A: With basic computer skills, you can start using the machine within a few hours. Practice and experimentation will enhance your proficiency over time.

Final Thoughts

A *laser cutter acrylic* machine is an invaluable tool for anyone looking to elevate their crafting or manufacturing capabilities. Its precision, versatility, and ease of use make it a worthwhile investment for both hobbyists and professionals. If you’re ready to take your projects to the next level, consider purchasing one today!

Looking for a reliable laser cutter acrylic machine? Check out our and find the perfect tool for your needs.