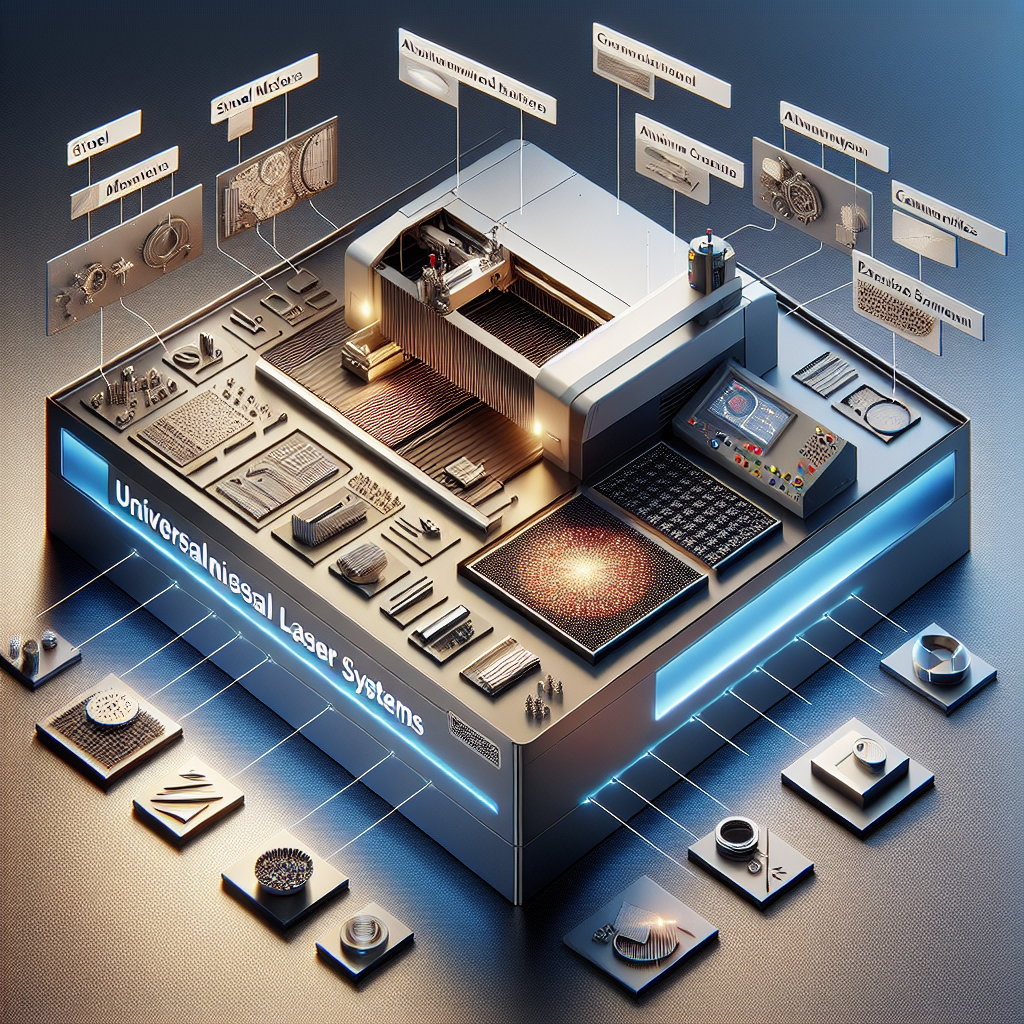

Universal Laser Systems Laser Cutter and Engraver: The Ultimate Guide for Precision and Versatility

When it comes to advanced manufacturing tools, few devices match the precision and adaptability of universal laser systems laser cutter machines. These cutting-edge tools have revolutionized industries ranging from aerospace to custom jewelry design. In this comprehensive guide, we’ll explore how universal laser systems laser cutter technology works, its applications, and why it’s a must-have for professionals seeking unmatched accuracy.

What Are Universal Laser Systems Laser Cutters?

Universal laser systems laser cutter machines are high-precision devices that use focused laser beams to cut, engrave, or mark materials. Unlike traditional mechanical tools, these systems operate without physical contact, minimizing material distortion and enabling intricate designs. Key industries relying on this technology include:

- Automotive (for custom parts and branding)

- Textiles (precision fabric cutting)

- Electronics (circuit board engraving)

- Medical device manufacturing (sterile component production)

Did you know? The universal laser systems laser cutter can process over 100 materials, including metals, plastics, ceramics, and even organic substances like leather.

Why Choose Universal Laser Systems Over Traditional Methods?

Traditional cutting and engraving methods often require multiple tools and setups, but universal laser systems laser cutter machines streamline workflows. Here’s why they dominate modern manufacturing:

- Speed: Laser systems complete tasks up to 5x faster than mechanical cutters.

- Accuracy: Achieve tolerances as tight as ±0.1mm for flawless results.

- Flexibility: Switch between materials without changing hardware.

- Cost Efficiency: Reduce waste and energy consumption by up to 40%.

Question: How do universal laser systems laser cutter devices handle heat-sensitive materials? Advanced cooling systems and adjustable power settings prevent warping or burning, even on delicate substrates like acrylic or silk.

Technical Specifications That Matter

When evaluating universal laser systems laser cutter machines, focus on these critical specs:

- Laser Type: CO2 vs. fiber lasers for different material compatibility

- Power Output: Ranging from 30W (for engraving) to 300W (for industrial metal cutting)

- Work Area: Standard sizes from 12″x12″ to 48″x96″

- Software Compatibility: Integration with AutoCAD, Adobe Illustrator, and proprietary platforms

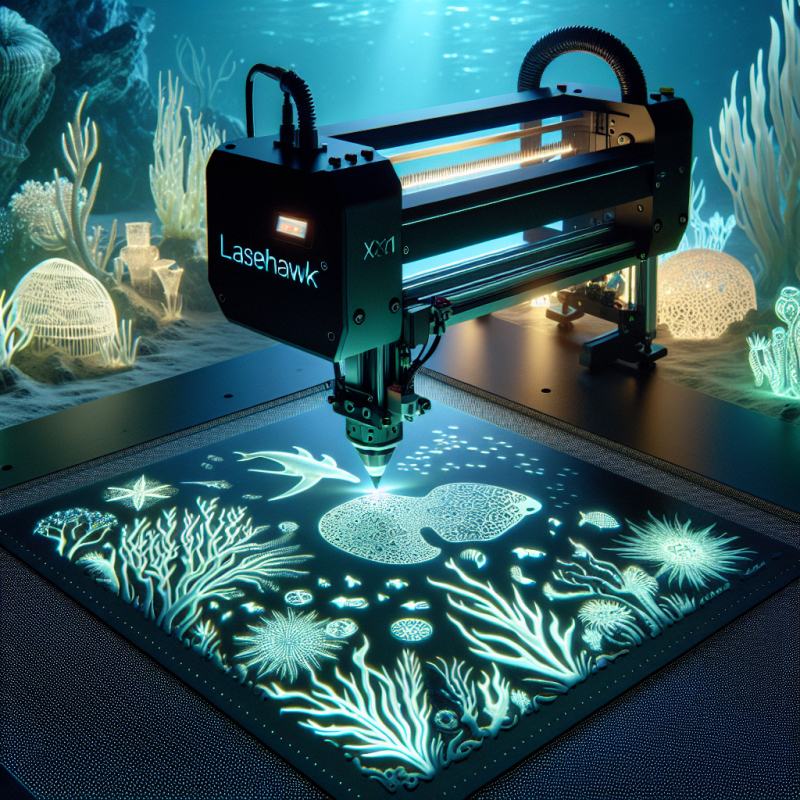

Pro Tip: For metal engraving, the universal laser systems laser cutter Hawk S1 model stands out with its enclosed diode design, ensuring safety and precision during prolonged operations.

Applications Across Industries

The versatility of universal laser systems laser cutter technology enables groundbreaking use cases:

- Art and Decor: Create intricate wooden sculptures or personalized glassware.

- Industrial Prototyping: Rapidly produce functional metal components for testing.

- Medical Tools: Engrave stainless-steel surgical instruments with permanent identifiers.

- Fashion: Cut leather handbags or etch metallic accessories.

Case Study: A Swiss watchmaker reduced production time by 60% after adopting a universal laser systems laser cutter for engraving titanium casings.

Safety and Maintenance Best Practices

While universal laser systems laser cutter machines are designed for reliability, proper maintenance is crucial:

- Use certified ventilation systems to remove toxic fumes

- Clean lens assemblies weekly with optical-grade solvents

- Calibrate laser alignment monthly

- Upgrade software firmware annually

Question: What safety certifications should your laser cutter have? Look for CE, FDA, and ISO 11553 compliance.

Future Trends in Laser Cutting Technology

The universal laser systems laser cutter ecosystem is evolving rapidly. Emerging innovations include:

- AI-Powered Optimization: Machine learning algorithms that adjust settings in real-time

- Hybrid Systems: Combining laser cutting with 3D printing capabilities

- Green Lasers: Energy-efficient models reducing carbon footprints by 30%

Prediction: By 2030, 70% of manufacturing facilities will integrate universal laser systems laser cutter machines into their core workflows.

Frequently Asked Questions

Q: Can laser cutters handle reflective metals like copper?

A: Yes, but only with specialized fiber lasers. The universal laser systems laser cutter Hawk S1 model includes anti-reflective coatings for such applications.

Q: How much training is required to operate these systems?

A: Most users become proficient within 8-12 hours. Manufacturers often provide certified training programs.

Q: What’s the average lifespan of a laser cutter?

A: With proper maintenance, expect 8-12 years of service. Critical components like laser tubes may need replacement every 2-3 years.

Conclusion

From small businesses to Fortune 500 companies, the universal laser systems laser cutter has become an indispensable tool for modern manufacturing. Its unmatched precision, material versatility, and evolving capabilities make it a smart long-term investment. Final question: Is your industry ready to leverage this transformative technology?